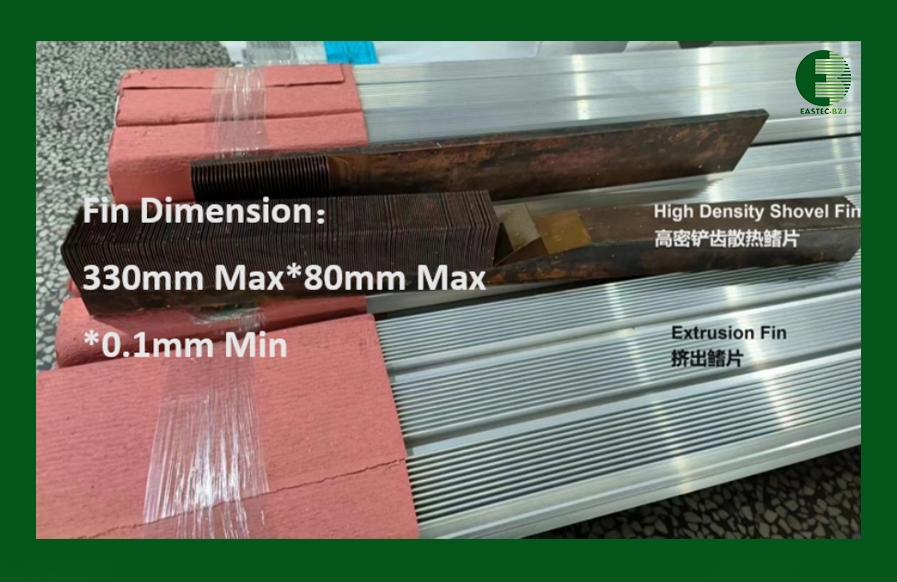

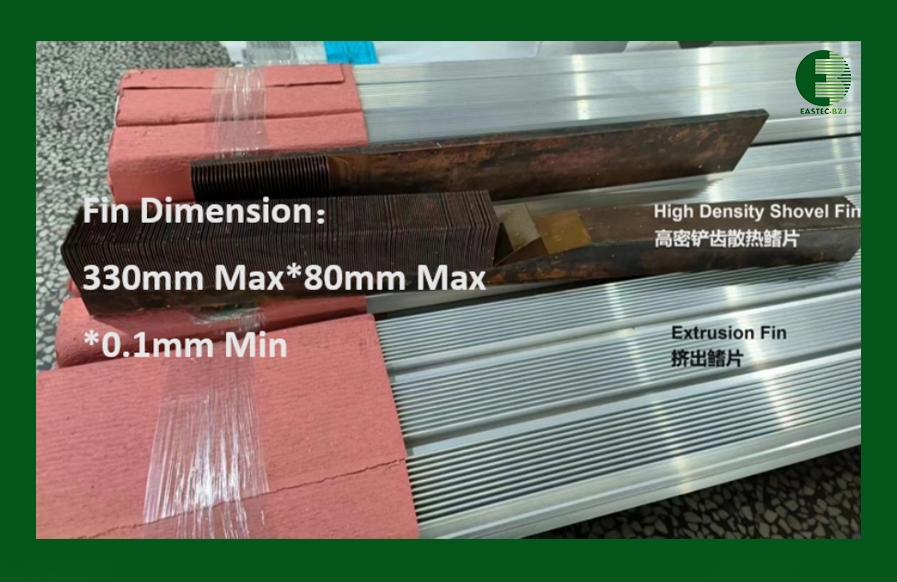

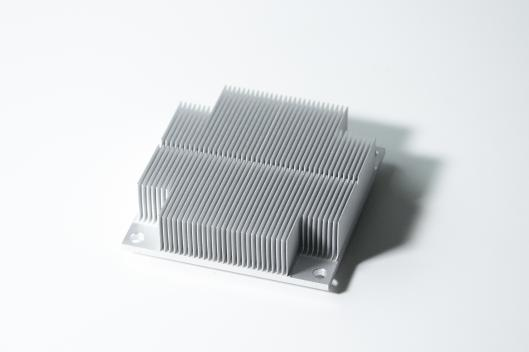

Heat sinks are one of the most common forms of thermal management components in technology, machinery, thermal sensitive equipment,and even in natural systems. Heat sink core function orients to increases the heat flow away from a hot device,and sometime it works as a protection cover at the same time. It accomplishes this task by increasing the device's working surface area and the amount of low-temperature fluid that moves across its enlarged surface area,named as thermal radiator. How to enlarge the surface area? Common technology is extrusion and it may achieve the thinnest fin 0.4mm min and fin space 0.5mm min. Eastec gives out shovel solution to run out spade fin to 0.1mm min and blade space level as 0.1mm min, the density 5:1 improved than extrusion parts. Eastec has the capability to process ultra-thin and extra-large extrusion fins with dimensions of up to a maximum width of 330mm and a maximum height of 80mm, achieving a minimum thickness and fin-gap as small as 0.1mm on limitless length shovel-fin bar with Cooper or Aluminium material.This significantly increased extrusion fin density compared to traditional processes leads to a substantial improvement in both heat dissipation efficiency and effectiveness since thermal-contact area increasing over 5 times than traditional extrusion-out parts.

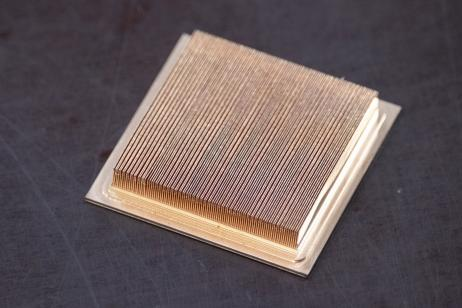

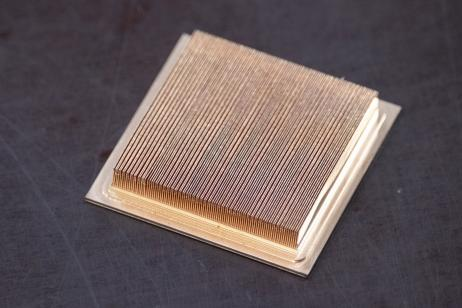

Copper and aluminum alloys are the primary constituent materials, each possessing unique advantages. Copper exhibits exceptionally high thermal conductivity, facilitating rapid heat transfer and contributing to efficient heat dissipation. However, copper's high cost, greater processing complexity, and relatively higher weight make it suitable for applications that demand higher performance.

In contrast, aluminum alloy materials are relatively more cost-effective and lightweight, although they have moderate thermal conductivity. Different application requirements will determine the choice of an appropriate type and material of heat radiator to ensure efficient heat dissipation and temperature control. The distinctive design and advantages of finned heat radiator make them the preferred heat dissipation solution across various industries.

We may analogy Cooper-Aluminum radiator with car-truck model,cooper radiator transfer thermal fast but with lower volume capacity,aluminum radiator in slow speed but may ship out bigger amount thermal-waste like a big truck. That is why we may see some IC adhesive with a Cooper-Aluminum heat sink, function concern sometime persuade engineers shrug shoulder to cost orientation.

1.Copper Material:

1)Thermal Conductivity: Copper is an excellent thermal conductor with high thermal conductivity, allowing for the rapid transfer of heat. This makes copper widely used in heat dissipation applications, especially in scenarios with high heat transfer requirements, such as electronic devices and computer IC.

2)Electrical Conductivity: Copper's high electrical conductivity means that electrical current can quickly pass through copper conductors, reducing electrical resistance losses. This is crucial for the thermal management and electrical connections of electronic devices.

3)Stability: Copper exhibits a high level of chemical stability and is resistant to corrosion, contributing to the long-term reliability of heat radiator.

4)Processability: Copper is easily processed and shaped, enabling the production of heat radiator in various shapes and structures.

2. Aluminum Material:

1)Lightweight: Aluminum alloys are relatively lightweight, making heat radiator manufactured from them more suitable for applications where reducing weight is essential, such as in the automotive and aerospace industries.

2)Cost-Effective: Aluminum alloys are typically more cost-effective, giving them a competitive advantage in cost-sensitive applications.

3)Moderate Thermal Conductivity: While aluminum's thermal conductivity is not as high as copper, it is still sufficient in many cases, especially in situations that require large surface area heat radiator.

4)Anti-Oxidation: Aluminum alloys can enhance their oxidation resistance through anodizing treatments, increasing the durability of heat radiator.

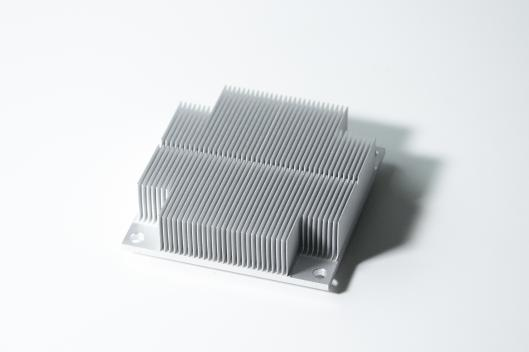

3.Manufacturing Process of Finned Heat radiator:

1)Raw Material Preparation: The production of finned heat radiator, as mentioned above, utilizes copper and aluminum materials as described in the previous sections. Initially, it's essential to select materials that meet the requirements, ensuring their quality and dimensions conform to the design specifications.

2)Fin-forming Process: This is the core step in the manufacturing of finned heat radiator. In this step, a solid piece of raw material is precisely cut from the top, then folded back to a position perpendicular to the base. The cutting and folding process is repeated to form a series of parallel fins with uniform spacing.

3)Cutting: The processed fins are cut to the desired size according to design specifications.

4)CNC Machining: CNC (Computer Numerical Control) machining is employed for precise cutting, perforating, and shaping to create the specific product features.

5)Surface Treatment: Aluminum or copper heat radiator undergo surface treatment to enhance their resistance to oxidation and corrosion. Typically, methods like anodizing,plating or coating are used to extend the heat radiator's lifespan and stability.

4.Challenges in the Processing of Finned Heat radiator:

1)Variations in Tooth Height and Thickness: The greater the differences in tooth height and thickness, the more complex the processing becomes. This complexity arises because the manufacturing process needs to ensure that each tooth has precise height and thickness to guarantee the performance and uniformity of the heat-dissipating fins. Significant variations can lead to uneven heat transfer, affecting the effectiveness of heat dissipation. To overcome this challenge, processing equipment and techniques must possess high precision and automated control to ensure consistent specifications for each tooth.

2)Tooth Density: If the teeth on the heat-dissipating fins are too densely packed, the density and spacing can complicate the processing. This necessitates processing equipment with higher speed and precision to maintain uniformity among the teeth.

3)Customization Requirements: Different application scenarios have varying size and shape requirements, requiring a more comprehensive consideration in terms of materials and processing, offering flexibility to align with practical applications.

5.Practical Applications of Finned Heat radiator:

1)Computers and Servers: Finned heat radiator are commonly used in computers and servers. Due to the significant heat generated during high-load operations of computers and servers, efficient heat radiator are crucial components to ensure system performance and stability.

2)Automotive Industry: Finned heat radiator are also widely employed in the automotive cooling systems, primarily for cooling engines and transmissions. They provide extensive cooling surfaces, helping to lower engine temperatures, enhance fuel efficiency, and extend the lifespan of vehicles.

3)Electronic Devices: Finned heat radiator find applications in various electronic devices, including televisions, sound systems, electronic communication equipment, etc. They are primarily used to stabilize the operating temperature of electronic components, preventing damage from overheating.

4)Medical Equipment: In the medical equipment sector, finned heat radiator contribute to cooling high-performance medical devices such as X-ray machines and magnetic resonance imaging (MRI) equipment. The medical industry places a higher demand on equipment stability, making reliable heat radiator critical.